Sweetener producer Manus, goals to democratize monk fruit manufacturing and availability within the US by way of fermentation at its facility in Augusta, Ga.

Monk fruit, an indigenous melon to Southern China’s Guangxi province, is without doubt one of the prime pure sweeteners within the US for its zero calorie and solubility throughout meals and beverage functions. Rising demand for monk fruit as a pure sugar-reduction ingredient prompted Manus, a producer of different pure sweeteners like stevia and Reb M, to construct a extra secure and sustainable provide chain, the corporate stated

“That’s the largest problem. [Monk fruit] is simply produced in a single a part of the world, in a single area,” which is the place biotechnology performs a job in creating a “scalable, cost-effective and sustainable manufacturing course of,” defined Ajikumar Parayil, founder and CEO, Manus.

Parayil continued, “Proper now, the issue for quite a lot of CPG corporations is that [monk fruit] is simply not accessible on the scale that they want, and there’s inherently numerous value and provide chain volatility.”

Made within the US

Manus’ fermentation-produced monk fruit emerged from a pilot program launched a number of months in the past, during which the corporate remoted mogroside V, the fruit’s candy, soluble, calorie-free compound that’s 250–400 occasions sweeter than sugar.

The fermentation course of required “greater than 30 totally different biosynthetic enzymatic steps” inside a single cell to supply the complicated mogroside, defined Christine Santos, chief expertise officer, Manus.

“We’ve now circumvented the entire technical and scale-up dangers related to this course of,” which permits Manus to progress in direction of pre-commercial scale at its pilot facility in Augusta, Ga., stated Santos.

The corporate is supplying kilogram-scale samples to prospects for formulation and product growth, with plans to scale to metric-ton manufacturing by yr’s finish

Manus’ scalable course of locations “monk fruit not simply as a distinct segment, pure sweetener, however now a sugar discount answer that may be deployed much more broadly [that] can be made within the US” throughout meals and beverage, stated Parayil.

Overcoming scalability challenges

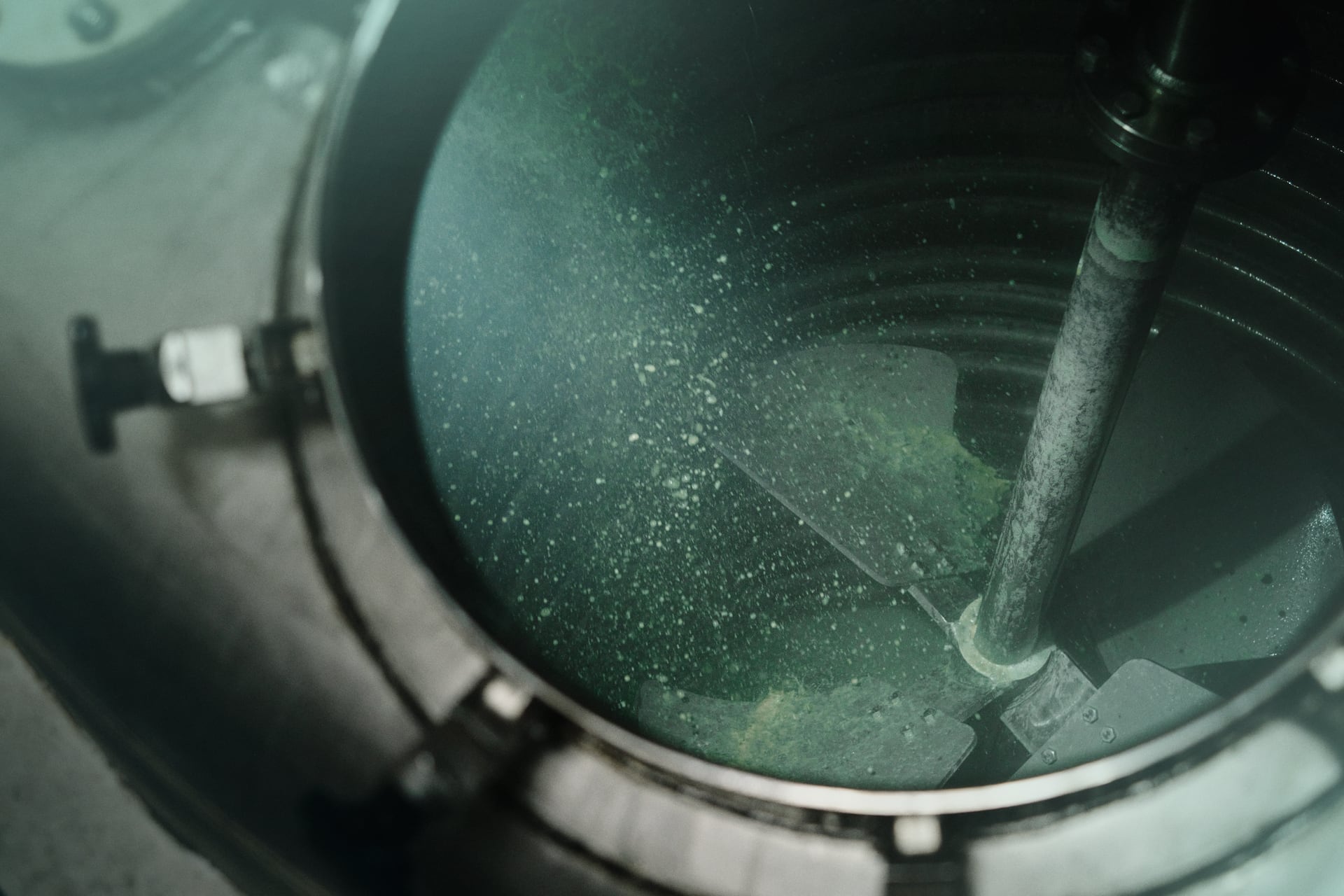

Past engineering cells to supply the sweetener, Santos notes scaling “a really sturdy fermentation course of” as one other problem. The corporate depends on food-grade, pressurized metal bioreactors to make use of inputs like glucose, to create “excessive yields of the ultimate monk fruit sweetener,” she defined.

To make sure a purified ingredient that aligns with shopper and CPG manufacturers’ clear label expectations, Manus makes use of a water-based, solvent-free purification course of for a soluble monk fruit that’s extremely concentrated and nature an identical, Santos stated.

“Once we give the product to prospects, it’s going to be simply mogrosides,” added Parayil.

Manus is presently engaged on the testing required for a closing GRAS discover and planning to launch its US-made monk fruit early this yr, Santos stated.